Overview

Power Transmission

We use our engineering expertise to meet the requirements of customers, supplying not only individual products but also units comprising existing components.

Home  Power Transmission

Power Transmission

Tsubaki Chain

Tsubaki RS G8 Roller Chains, the world's most trusted brand in power transmission chains.

Efficient and reliable transmission of ...

Features

1.Tsubaki Drive Chain

Efficient and reliable transmission of ...

Tsubaki Cable Carries / Cableveyor

Tsubaki cable carries are devices for electric cable and hydraulic or pneumatic hoses that can be install inside so that they can reliably supported and ...

Tsubaki Motion Control

Cam Clutches are precision devices which lock the inner and outer races, through the wedging action of cams, to transmit torque in one direction of ...

Nidec Shimpo Reducer

Nidec-Shimpo Corporation’s power transmission technology combines both mechanical and electrical engineering advancements has an extensive track record in various applications on tension and winding control, ...

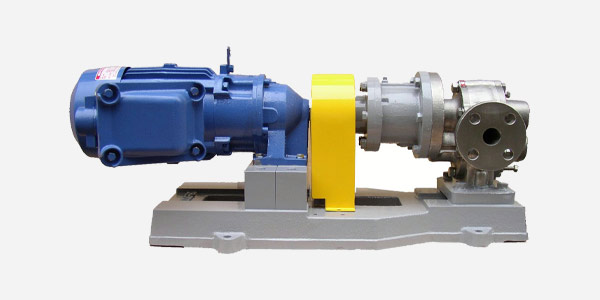

Daito Kogyo Pump

Daito Kogyo Pump products are approved for high-pressure gas and can also be manufactured. Jacket and built-in safety valve are available.

Features

Features ...

Kyowa Universal Joint

The technology developed 50 years before, such as materials, heat treatment and a hundred percent qualified products, has improved its durability, and changed the universal ...

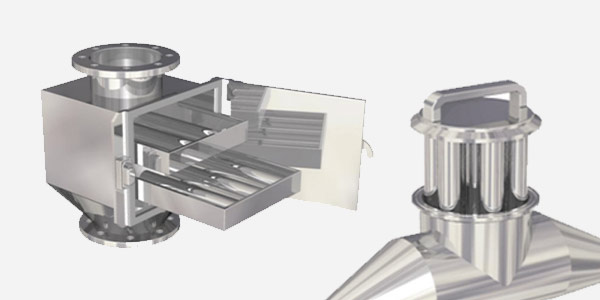

Magnetec Japan Ltd

Magnet separator is an equipment can remove or separate metal contamination by using magnetic force. Not only steel but austenitic stainless stell fine powder as ...

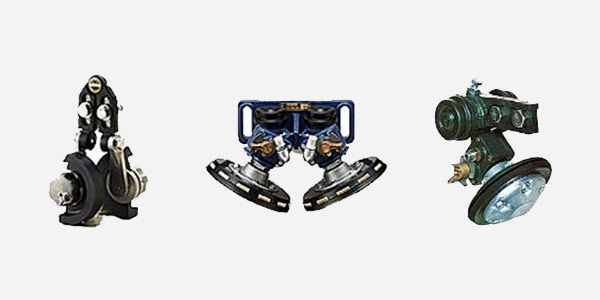

Flexco

Flexco are committed to keeping your belts and your business moving, goes beyond manufacturing belt fasteners, cleaners, and maintenance products to developing real solutions to ...

Futec Origin Lubricator

Futec Origin Lubricators reduce wear and tear on the wheels, effectively extending the life span and service interval while reducing on maintenance time and cost. ...

Shinko Seiki

For your "One-Stop" Vacuum Consultant, Shinko Seiki. Correct solution provider with wide variety of vacuum pumps against customer’s vacuum needs and current issues. Application based ...

Mubea

Mubea has specialized in the production of high-quality disc springs for over 40 years. Because of their versatility, disc springs are used extensively in a ...

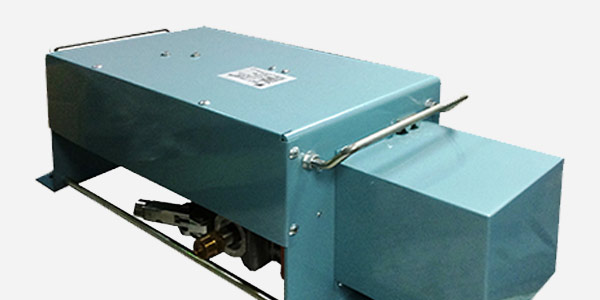

Daikin Lubrication

The Daikin Chain Grease Feeder automatically distributes the right amount of grease to reduce grease wastage, labour and time taken for maintenance, energy consumption, while ...

MP Foods series

MP Foods series can be a solution for contamination of soft foreign objects in Food industry. MP Foods series stick the magnet in spite of ...

Industrial Sensors

Industrial sensors play an important role in detecting and sending signal for analysing and processing before these data can be translated into results like alarms ...

Industrial Inverter / Gear(Box & Motor)

Gear motors typically uses gears assembled as a gearbox to deliver high torque at low horsepower or low speed. The common applications of gear motors ...

Interroll Drum Motors and Roller

The Interroll Drum Motor platform allows you to create belt drive solutions made of standardized, high-quality components that meet your exact needs and are compatible ...

MVE Standard Range

For changing Products Direction and Zero or Small Inner Radius 180 degree Curves.

Interroll Carton Flow Picking Solution. The picking of goods ...

MVE-Exd Explosion-Proof

Electric vibrating motors for applications in the Oil & Gas sector and wherever safety regulations explicitly require explosion proof certification, according to the International Standards ...

MVE-F Flanged Vibrators

Electric vibrating motors for applications in the Oil & Gas sector and wherever safety regulations explicitly require explosion proof certification, according to the International Standards ...

MVE-SV Screen Vibrators

The MVE-SV are "long" electric vibrators, with foot fixing on the ends of the body. They are available in 4-pole version with different voltages, suitable ...

PS – Hammers

The PS series hammers produce a high impact force thanks to a single impact between the internal piston and the metal base welded on the ...

S – Pneumatic rotational vibrator – Ball

The OLI "S" series pneumatic rotational vibrators generate high frequency vibration thanks to a steel ball that rotates inside two housings made of hardened and ...

OWC – Rubber Oscillating Suspension

OWC oscillating suspension assure a high shock-absorbing level due to their special shape featuring the interaction of four elastic torsional elements.