Home  Tsubaki Labo Stocker

Tsubaki Labo Stocker

Tsubaki Labo stocker provides total solution for storage system at ultra low temperatures for vials, test tubes, DNA samples etc. It is an automated storage system from entry to delivery of samples. Labo Stocker is applicable to minus 150 degrees C environment.

Labo Stocker

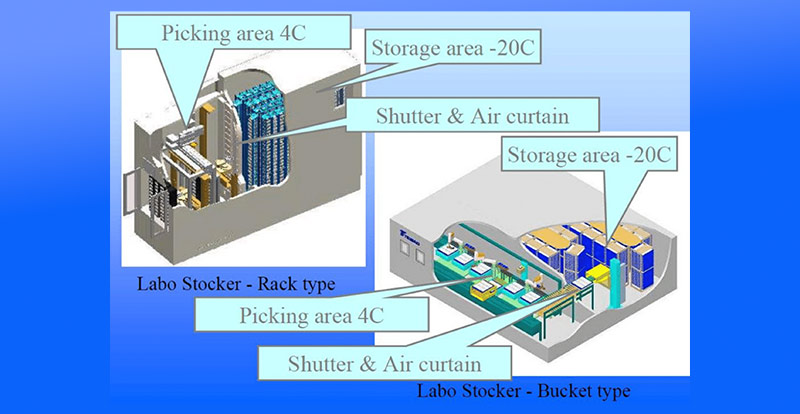

- Bucket type

Quantities of samples storage – More than 500K samples (Vials & tubes)

- Rack type

Quantities of samples storage – Less than 1,000K samples (Tubes & plates)

Standard specification

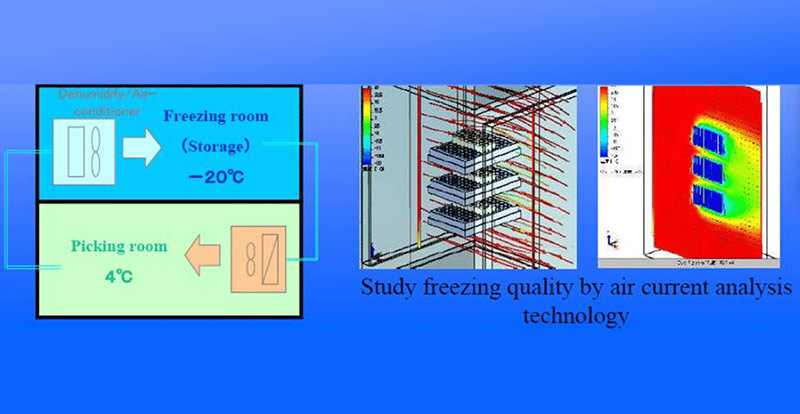

- Prevent dew forming by air circulation

Controlling absolute humidity between storage and picking area - Multi Air-conditioning system

Temperature to be controlled even if one air-conditioning system has a problem - Save-energy operation when system has a blackout planning

Controlling temperature at storage area only. Electricity tobe 1/3 of standard usage. - Keep air circulation space for temperature control

Supply record for University/Institute/Laboratory/Pharmaceutical

- The Institute of Medical Science, The University of Tokyo

– DNA storage system (Labo Stocker)

– Serum storage system (Freezing vessel)

- Faculty of Pharmaceutical Sciences, The University of Tokyo

– Powder compound storage system (Labo Stocker)

– Liquid compound storage system (Labo Stocker)

- Faculty of Medicine, Kyoto University

– DNA storage system (Labo Stocker)

RIKEN – DNA storage system (Labo Stocker)

– Compound management system

- National Institute of Advanced Industrial Science and Technology

– Cell storage system (Freezing vessel)

- Nagoya University and others-DNA sample management system

– Compound storage system (14 Labo Stockers)

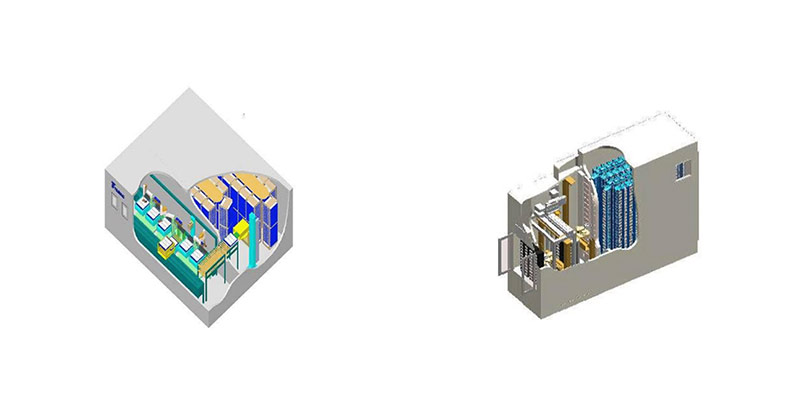

Bucket Type (Left) / Rack Type (Right)

Features

DNA Dispensing System:

- Dispensing:

From micro-tube (Delivery from automated storage system and tubes in rack.) to 96 well shallow plate

- Ability:

10 minutes (If the case of micro-tube and plate are 1 by 1.)

Volume–50microns (Volume can be changed as per request.)

- Work process:

Work process of automated dispensing

-De-capping of micro-tube

-Dispensing to shallow plate

-Capping to micro-tube

-Capping to shallow plate

-Transferring the result data

Product Specialist

- Harrison chu

- +65 6862 6800

Request Callback

Solutions Consultant

- In person

- Monday to Friday from 7 am

- Saturday from 8 am

Sector

Find more Sector.

In the heavy objects transport process, it is suitable for the work of lifting from waist-height to chest level and carrying horizontally avoiding obstacles above.

Sector 1

We handle all aspects of an integrated.

Sector 1

We handle all aspects of an integrated.

Sector 1

We handle all aspects of an integrated.

Sector 1

We handle all aspects of an integrated.

Sector 1

We handle all aspects of an integrated.

Sector 1

We handle all aspects of an integrated.

Sector 1

We handle all aspects of an integrated.

Sector 1

We handle all aspects of an integrated.

Power Transmission

Brands

Factory Automation

Brands

Environment

Brands

Product Specialist

- Harrison chu

- +65 6862 6800

Request Callback

Solutions Consultant

- In person

- Monday to Friday from 7 am

- Saturday from 8 am